Orthopaedic

Surgical Implants

Upper & Lower Extremity & Trauma

Our support to our customers begins during their design stage where we provide inputs and expertise focused of the manufacturability of the part. We assist in the focus of meeting precise tolerances along with the ability of repeatability of the manufacturing process.

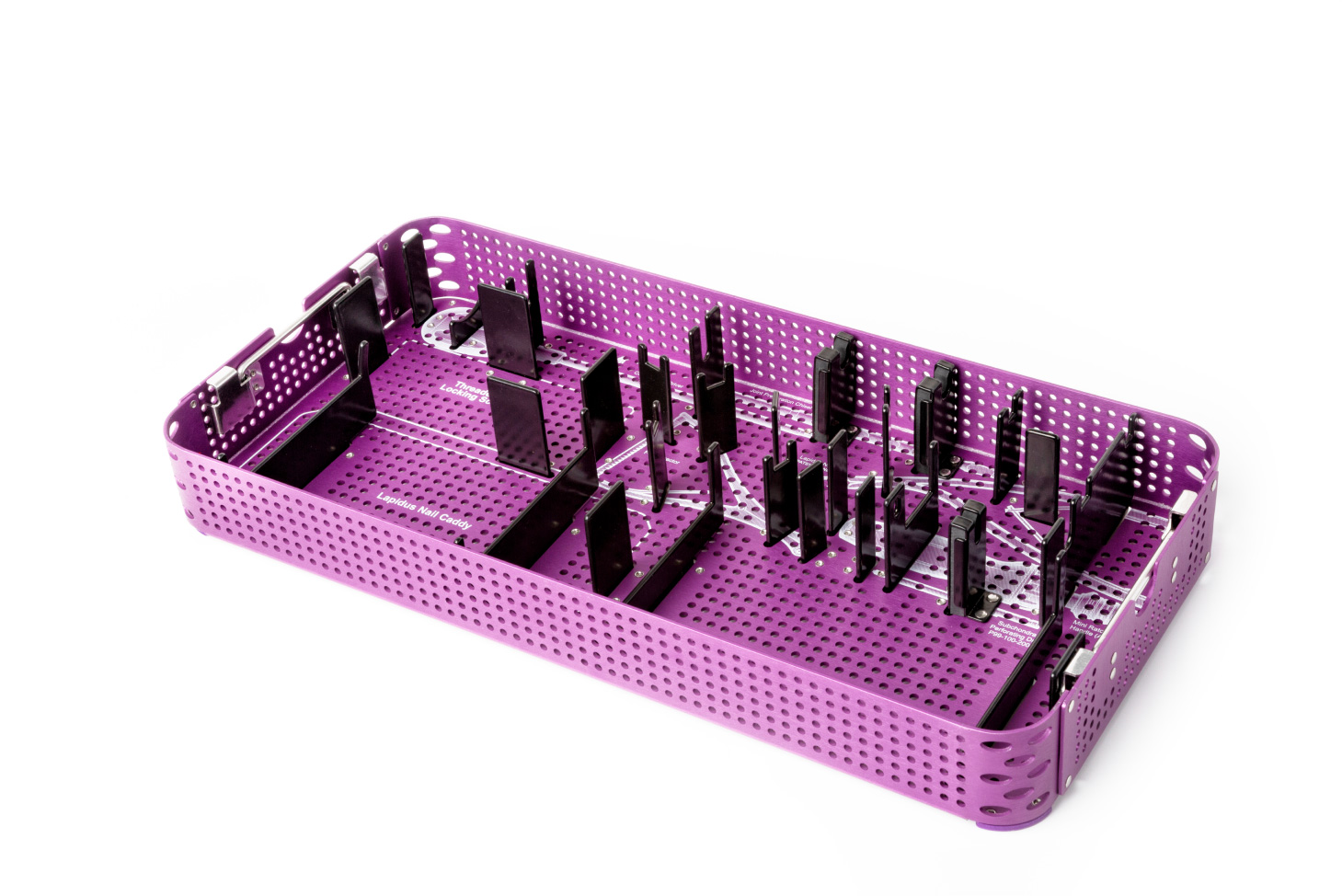

From production of plates and screws to complex assemblies to spinal rods, our team’s deep industry expertise is matched by precise manufacturing experience and in-house capabilities. Our comprehensive offerings include not just manufacturing the part, but how to measure that part. Our team designs and develops custom fixtures and gauges to ensure parts are made to the specification requirements.

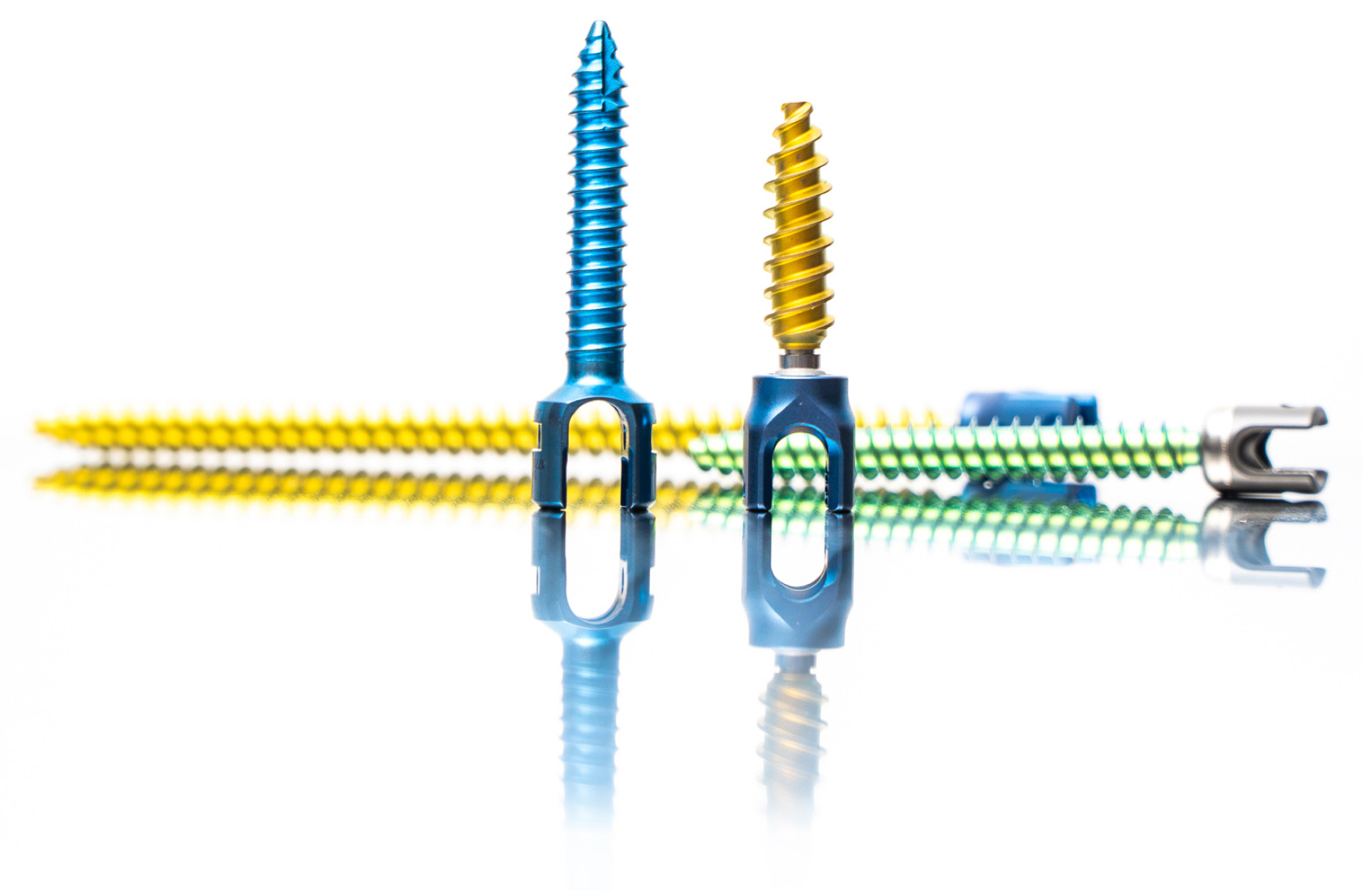

In addition to assemblies our finishing processes include Type II and III titanium anodization, passivation and laser marking Custom packaging and labeling complete the process.

Anodization & Laser-Marking In-House

Laser Marking

Laser Marking is ideal method used for part identification (lot number marking/traceability, part numbers, customer logos, UDI numbers, and measurement graduations.

Our in-house laser marking solution allows for a one-stop implant production, without waiting on others for turnaround, and lead times.

Anodization

Implants are often anodized for efficient and clear visual part identification (i.e. left or right, size identification), or kitting with matching screws.

Our in-house Type II and Type III titanium anodization station allows us to color your parts, per custom specifications.

- Design and Development Capabilities

- Finishing Capabilities

- Graphics

- Manufacturing Capabilities

- Quality Commitment

- Limited Outsourcing

- Time Sequencing

Learn more about:

Medical Manufacturing SPECIALISTS

Velocity is dedicated to sharing your unique vision of the future.

Your product is our passion – that’s why we focus on streamlining processes between our business and yours. Our engineering and design teams’ interface with all standard formats, which minimizes delays and speeds product to the manufacturing phase. Our processes are built to capture the finest details within your requirement set, and our tenured design team members can quickly identify and help you navigate any risks to timeline or design errors that might emerge before the manufacturing process is initiated. All Velocity customization processes and team members are honed to allow the best experience for the end user – which means your product will make the impact it should, every time.