Custom design, precisely manufactured

Orthopaedic delivery systems, implants, and instruments.

As your full-service integrated partner in orthopedic medical devices, our experts do more than engage with you on your project, we collaborate end-to-end, guiding and supporting you every step of the way. We have deep clinical understanding, unparalleled experience in custom orthopaedic manufacturing, and acute focus on meeting the needs of the ultimate end customer – the surgeons and care teams who use your solutions day in and day out.

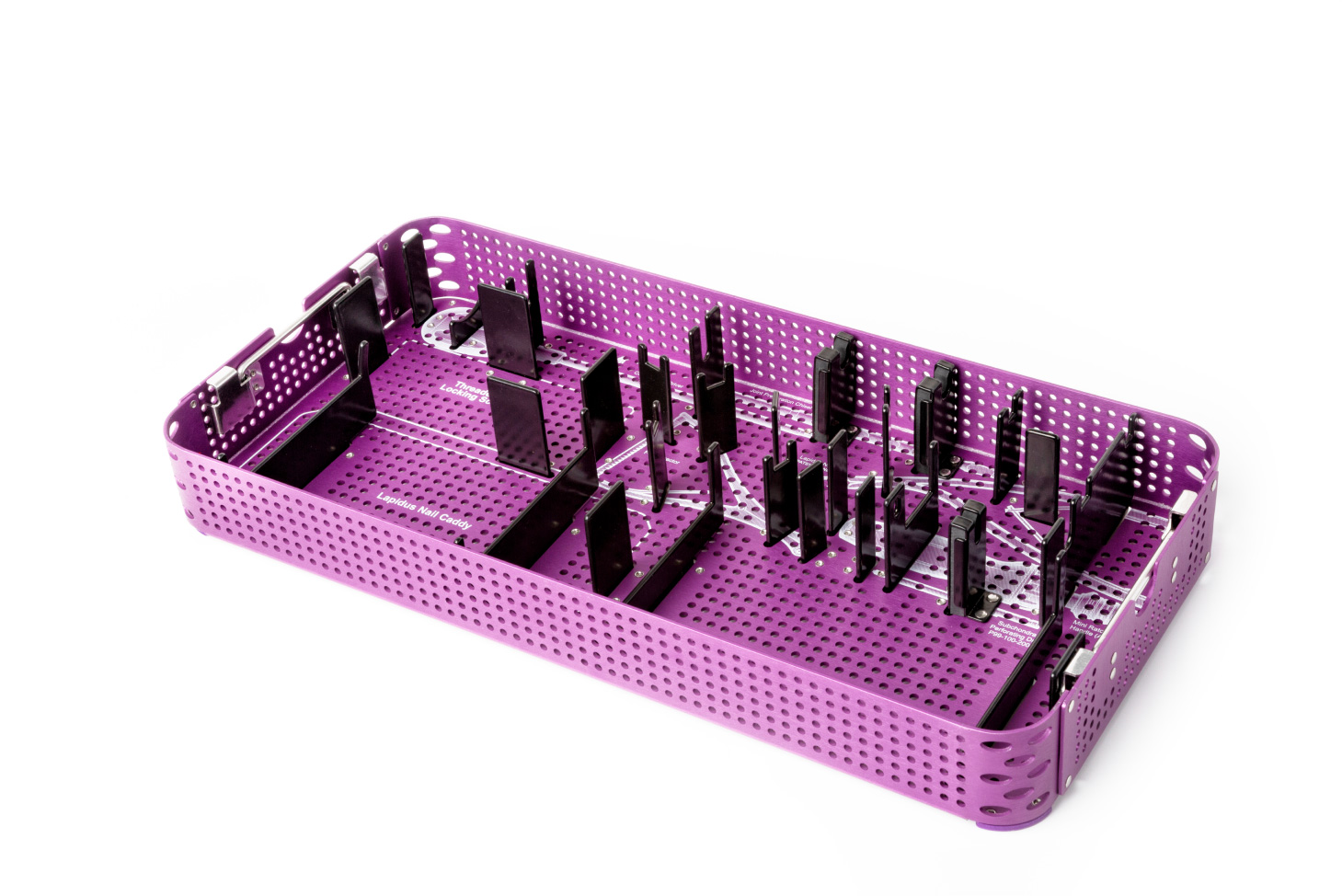

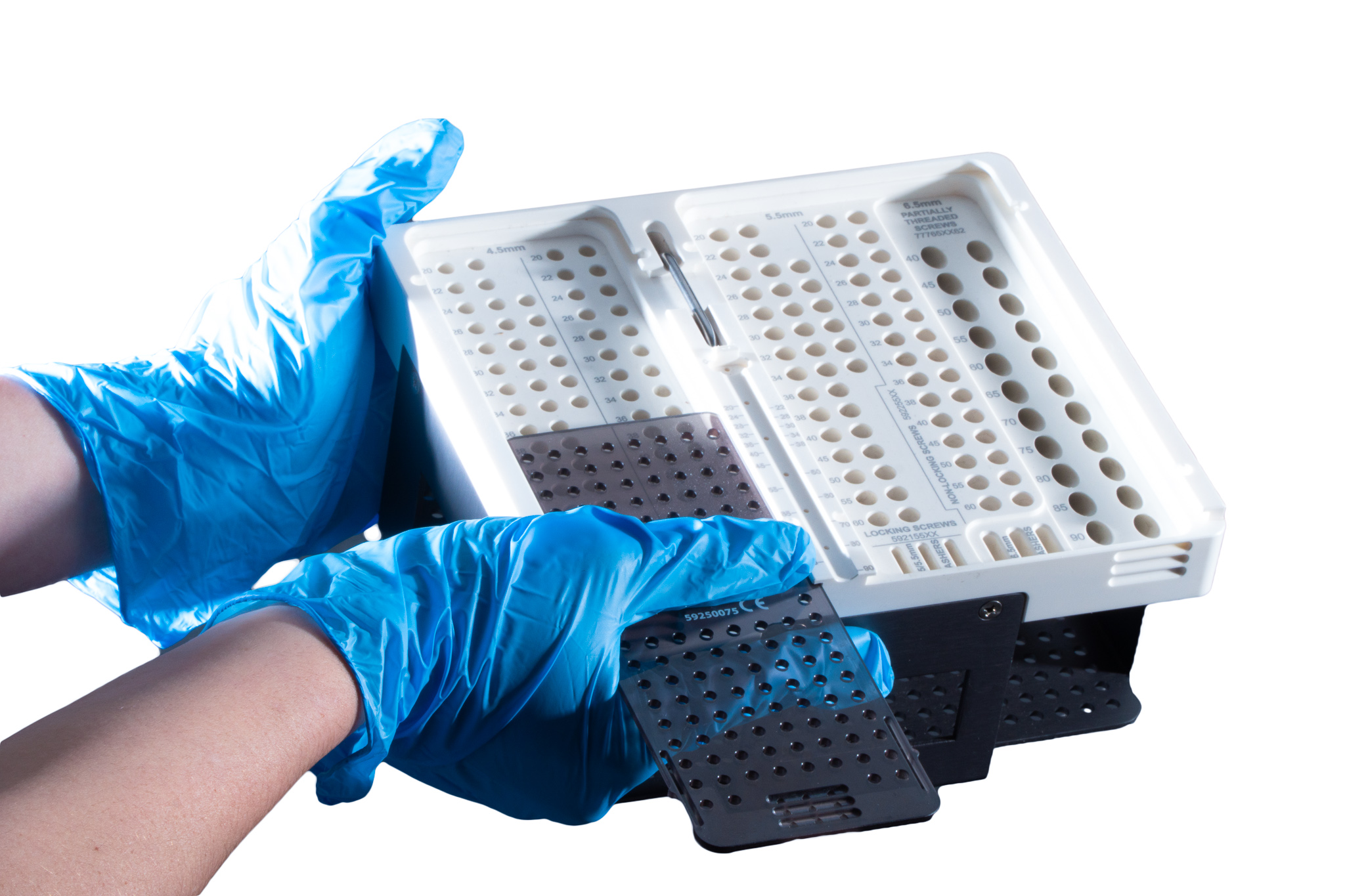

Custom Cases & Trays

With over 50 years of designing and manufacturing orthopaedic cases and trays, our teams at Velocity use our vast experience to optimize your solutions. We offer custom branding, painted design elements including logos, corner finish options, and meet internal design preferences to best serve the surgical teams who use our products.

- Design, Design process validation, Design transfer expertise

- Surface finish anodization, nylon coating

SHOP PROTOTYPE SAMPLES

Caddies

Our orthopaedic caddy specialists custom design and manufacture caddies to meet our customers end-use needs. We take your inputs and use our expertise to design the optimum lay-out for your components.

Our expertise includes caddy labeling, marking, and decorating to insure the end-users ease of, and efficient use.

Implants

At Velocity, we specialize in custom, built to order trauma, upper and lower extremity, and spine implants such as plates, screws, and more. Implant manufacturing requires specialty knowledge and manufacturing process requirements. We live and breathe the intricacies related to part validation and regulated documentation. Each implant is manufactured to precise specs in a tightly controlled environment.

We use precision manufacturing techniques to reliably meet tight tolerances and offer type-two and type-three anodizing in-house. This allows us to strictly manage QA while providing our customers with the flexibility and value they deserve.

Instruments

From drivers, to drills, taps, guides, sizers and beyond, we deliver both re-usable and single use/disposable instruments for surgical applications. We consult with our customers to manage design and manufacturing challenges such as tolerance stack-up and assist with engineering for repeatable cost-effective manufacturability. We optimize the manufacturing and assembly process from production to testing and procurement to shipping and delivery.

Medical Specialties

Our expertise spans a wide array of orthopaedic specialty areas.

Partnership that Works from Start to Finish

We partner together from design for manufacturing, to first article, product qualification, and production, through assembly, supply chain integration, delivery, and beyond.

From custom anodization, to specialized branding, surgeon-preferred design, and beyond – we’re flexible, nimble, and experienced, and ready to support your manufacturing needs.

In-House Expertise

The Velocity Advantage for Rapid Go-To-Market Goals

We complete all engineering, manufacturing, anodization, kitting, and packaging in-house. Our experts apply our experience and industry knowledge to your medical device and validation needs. Your all-in-one, comprehensive resource.

Kick Up the Velocity

Velocity is dedicated to sharing your unique vision of the future.

Ready to start the custom design and manufacture of your Orthopaedic delivery systems, implants, or instruments? Regardless of where you are in the concept, design, or manufacturing process, start with a complimentary consultation today.