Custom Orthopaedic

Caddies

Functional, Flexible Solutions.

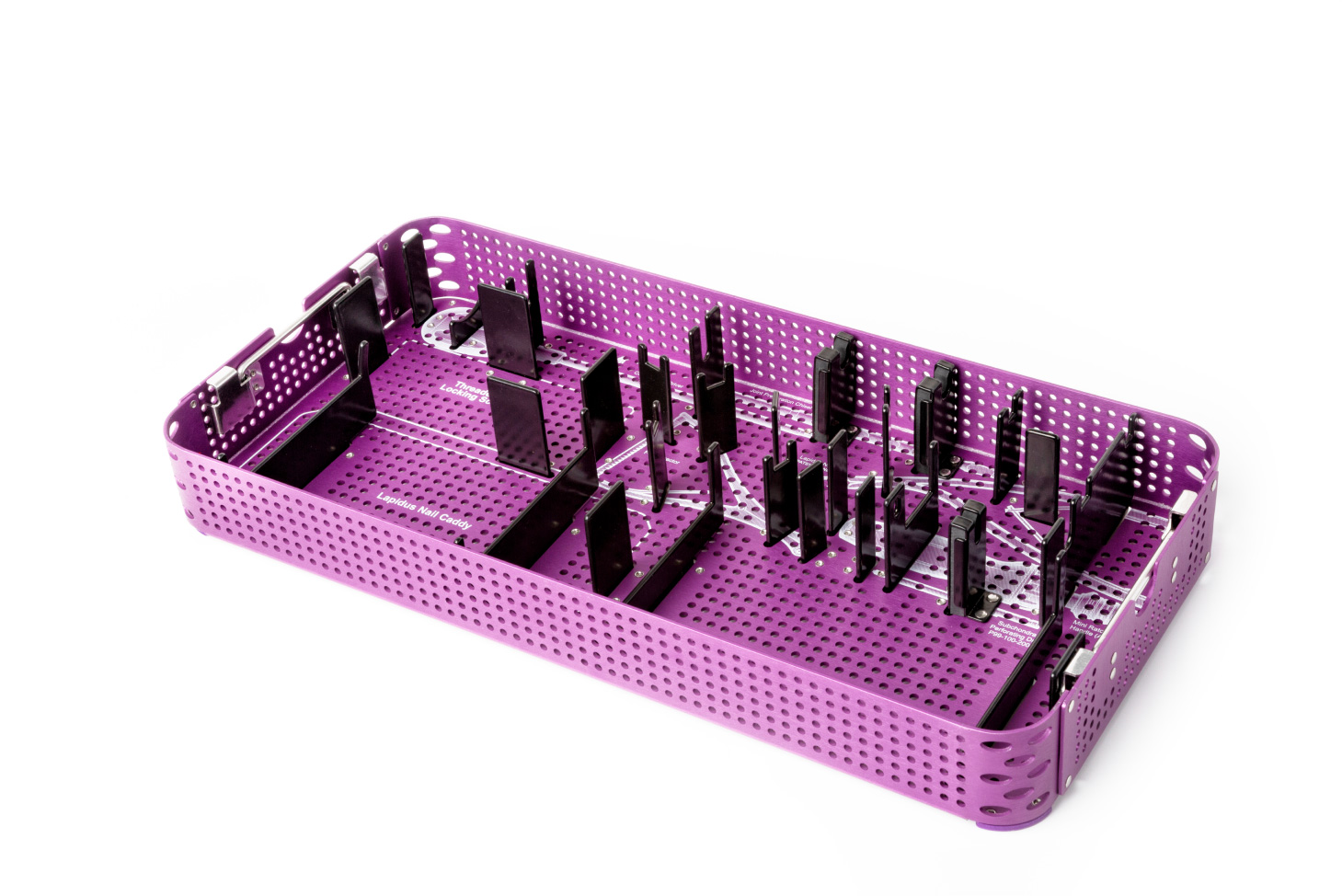

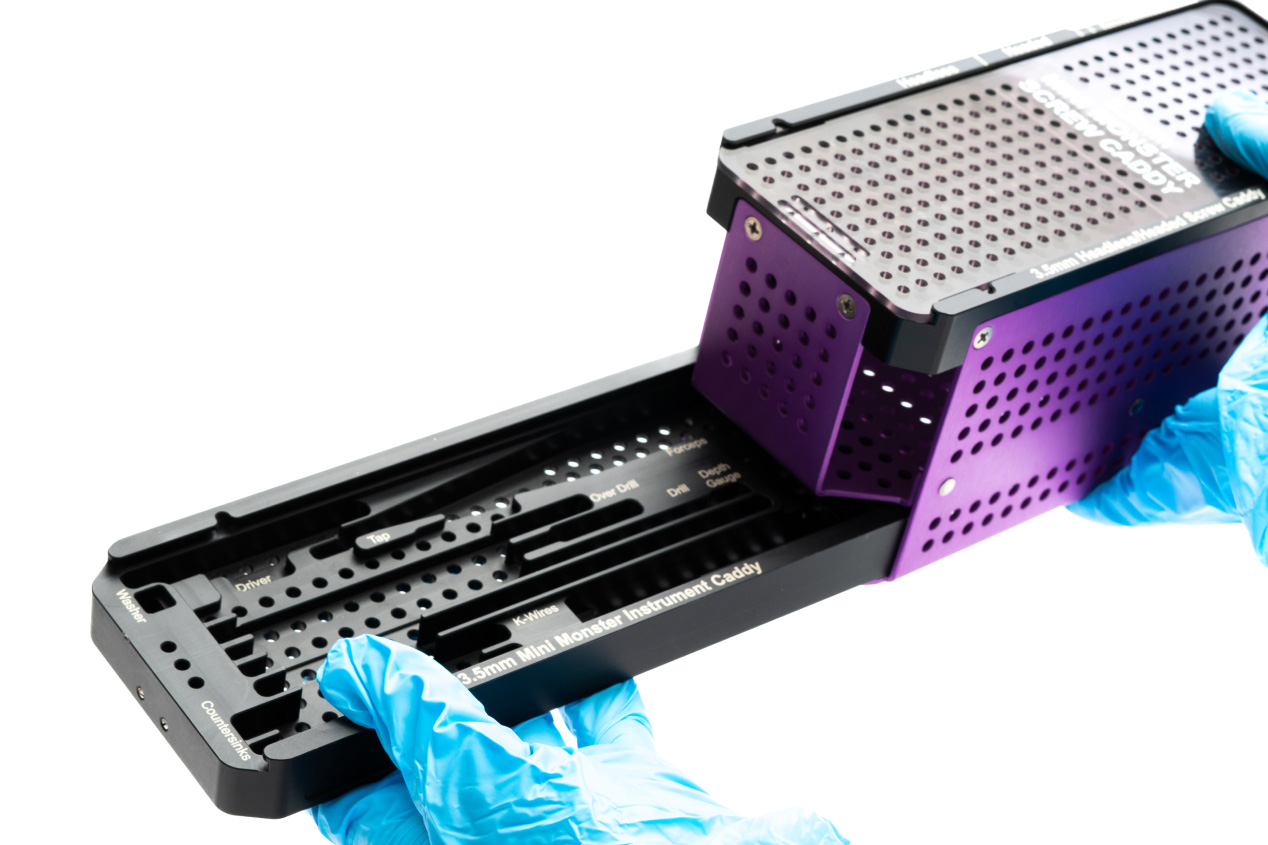

Our caddies are all designed and machined in-house using both plastic and metal material options. Each caddie can be branded or labeled, via silk screen or laser etch) for quick and reliable component identification.

Share with us your surgical application needs , and we will collaborate to thoughtfully design a solution for functionality and ease of use. Through an agile, iterative design and approval process, we will capture and execute a caddy solution that will make accessing the components during surgical procedures seamless.

Ease of Use is Key

Caddies may seem like a small part of the equation in the operating room, until you find your caddy solution doesn’t support the surgical procedure – then it’s a showstopper. We design solutions so that the teams that use them day in and day out can focus on the surgery itself, and the supporting components are accessed with ease.

Understanding providers have preferences in their interaction and access for caddy components. We collaborate with you to design a solution that allows efficient and streamlined engagement in the operating room.

Ease of Use is Key

Comprehensive Expertise,

In-House Capabilities

- Modularity

- Interchangeability

- Stackability

- Inventory Management

- Labeling/Traceability

- Brand Identity

- Instrument Identification and Accessories

Overall Process Control

- Design and Development Capabilities

- Finishing Capabilities

- Graphics

- Manufacturing Capabilities

- Quality Commitment

- Limited Outsourcing

- Time Sequencing

Learn more about:

Medical Manufacturing SPECIALISTS

Velocity is dedicated to sharing your unique vision of the future.

Your product is our passion – that’s why we focus on streamlining processes between our business and yours. Our engineering and design teams’ interface with all standard formats, which minimizes delays and speeds product to the manufacturing phase. Our processes are built to capture the finest details within your requirement set, and our tenured design team members can quickly identify and help you navigate any risks to timeline or design errors that might emerge before the manufacturing process is initiated. All Velocity customization processes and team members are honed to allow the best experience for the end user – which means your product will make the impact it should, every time.